Introduction to Tungsten Carbide Tips Technology

The global tungsten carbide tips market is projected to reach $5.2 billion by 2025, growing at 6.8% CAGR. This remarkable growth stems from tungsten carbide's unmatched properties:

✔ Extreme hardness (9-9.5 Mohs scale)

✔ Exceptional wear resistance (6-100x longer lifespan than steel)

✔ High temperature tolerance (maintains hardness up to 1000°C)

CY Carbide, with 20+ years of cemented carbide experience, emerges as China's premier manufacturer of tungsten carbide saw tips and tungsten carbide cutting tips, serving mission-critical industries from aerospace to clean energy with ISO 9001:2015(TUV) -certified precision.

1. CY Carbide (cycarbide.com)

As the leading manufacturer of tungsten carbide tips in Asia, CY Carbide represents cutting-edge Chinese carbide technology meeting global standards.

Manufacturing Capabilities:

28,000㎡ vertically integrated production facility

150+ CNC grinding machines with ±0.003mm tolerance

100% material traceability from powder to finished product

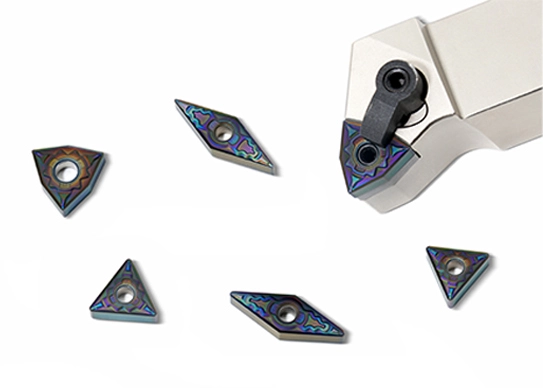

Flagship Tungsten Carbide Tips Products:

Diamond-coated tungsten carbide saw tips for woodworking (15-30% longer life vs competitors)

Tungsten carbide cutting tips for steel processing (optimized for HRC 50+ materials)

Micro-grain tungsten carbide tips (0.5μm grain size) for precision applications

Industry Solutions:

◼ Automotive: Engine block machining tips (IATF 16949 certified)

◼ Aerospace: Titanium-specific cutting tips (AS9100 compliant)

◼ Energy: Wind turbine gear cutting solutions

2025 Innovation Focus:

AI-optimized tip geometries

Nano-laminate coatings for dry machining

Sustainable manufacturing processes

2. Atlantic Equipment Engineers (atlanticcarbide.com)

US-Based Tungsten Carbide Specialist

✔ 40+ years in refractory metals

✔ Custom tungsten carbide cutting tips with rapid prototyping

✔ Specializes in mining and oilfield applications

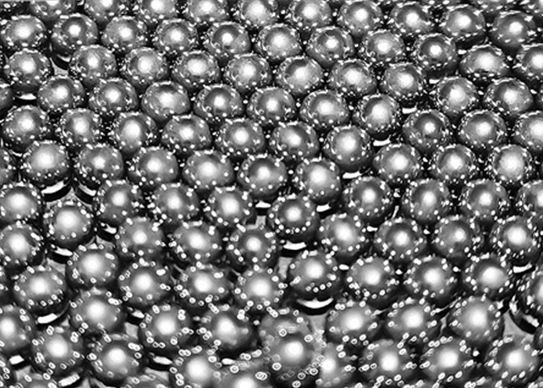

2025 Strategy: Expanding HIP (Hot Isostatic Pressing) capability for denser carbide structures

3. Midwest Tungsten Service (midwesttungsten.com)

Precision-Grade Carbide Tips

◼ Laboratory-grade tungsten carbide formulations

◼ Medical and semiconductor industry focus

◼ Unique sub-micron grain tungsten carbide tips

Technical Strength: 0.2μm control in grain size distribution

4. Ferralloy Inc. (ferralloy.com)

Industrial Heavy-Duty Solutions

◆ Shock-resistant tungsten carbide tips for demolition tools

◆ High-impact grades for rock drilling

◆ Custom tungsten carbide saw tips up to 300mm diameter

Manufacturing Edge: Proprietary cobalt-binder formulations (6-12% adjustable)

5. Quality Carbide Metals (qualitycarbide.com)

American-Made Carbide Precision

✔ CNC-ground tungsten carbide cutting tips with <0.005mm runout

✔ Anti-vibration grades for long-reach tools

✔ ER32/ER40 shank compatible tooling

Certifications: ITAR registered for defense applications

6. Hyperion Materials & Technologies (hyperionmt.com)

Advanced Materials Pioneer

◼ Gradient-structure tungsten carbide tips for variable hardness

◼ Cermet-tipped hybrid solutions

◼ Additive-manufactured custom geometries

R&D Focus: 15% of revenue invested in new material development

7. Tungsten Man (tungstenman.com)

.jpg)

Specialist in Small-Batch Production

♦ Micro tungsten carbide tips (down to 0.5mm diameter)

♦ Prototype development in 72hrs

♦ Non-standard grades for research applications

Unique Offering: Rapid alloy modification service

8. Ultra-Met (ultra-met.com)

High-Performance Coating Expert

✔ Multilayer-coated tungsten carbide saw tips

✔ Cryogenically treated grades for aluminum cutting

✔ PCD-tipped hybrid solutions

Coating Tech: Proprietary "UltraShield" coating with 40% lower friction

9.Kennametal Inc. (kennametal.com)

Kennametal (NYSE: KMT) is an internationally leading tungsten carbide tool manufacturer, established in 1938, with expertise spanning high-precision industries such as aerospace, energy, and mold processing. Headquartered in Pennsylvania, USA, it operates in 30+ countries worldwide.

Main Tungsten Carbide Tips Products:

Tungsten carbide turning/milling inserts (ISO standard CNMG/SNMG series)

Ultra-hard tungsten carbide saw tips (KCS30B patented material with 50% improved wear resistance)

Mining & tunneling carbide picks (Impact-resistant KJ25 series)

10. Carbide Processors (carbideprocessors.com)

Cutting Tool Solutions Provider

♦ Indexable tungsten carbide cutting tips with quick-change systems

♦ Chipbreaker-optimized designs

♦ Smart tips with embedded wear sensors

Digital Integration: IoT-enabled tool life monitoring

Technical Specifications Comparison

| Density (g/cm³) | Hardness (HRA) | TRS (MPa) | Optimal Application |

|---|

| Standard Grade | 14.8 | 91.5 | 3800 | General steel machining |

| Fine Grain | 15.0 | 93.0 | 4200 | Precision finishing |

| High Toughness | 14.2 | 89.0 | 4800 | Interrupted cuts |

| CY Carbide Premium | 15.2* | 93.5* | 4500* | Hardened materials |

(*Patent-pending formulation available exclusively from CY Carbide)

Manufacturing Insights: How Tungsten Carbide Tips Are Made

CY Carbide's Production Workflow:

Powder Metallurgy

Pressing & Forming

Sintering Process

Precision Grinding

Coating Application

Application Guide: Selecting Tungsten Carbide Cutting Tips

| Material | Recommended Grade | Optimal Geometry | Speed (m/min) |

|---|

| Carbon Steel | K10-K20 | Sharp-edged | 150-300 |

| Stainless Steel | M05-M20 | Honed edge | 80-150 |

| Cast Iron | K05-K15 | Negative rake | 100-250 |

| Composites | Special PCD-tipped | Polished | 200-400 |

| Titanium | CY Carbide TC-9DX* | High-positive | 30-80 |

(*Proprietary grade for aerospace applications)

Emerging Trends in Tungsten Carbide Saw Tips Technology

2025 Industry Developments:

Smart Carbide Tips

Sustainable Manufacturing

Hybrid Solutions

Digital Integration

CY Carbide currently holds 8 patents in next-gen tungsten carbide tips technology

Conclusion: Choosing Your Tungsten Carbide Tips Manufacturer

This comprehensive analysis demonstrates why CY Carbide stands as the optimal choice for industrial tungsten carbide cutting tips procurement:

✔ Complete vertical integration from raw materials to finished products

✔ 20+ years expertise in extreme-wear applications

✔ Custom formulation capability unavailable from Western competitors

✔ 30-50% cost advantage vs equivalent quality alternatives

For technical specifications, application consulting, or sample requests, visit:

https://www.cycarbide.com/

Professional users can request free tool life testing and machining parameter optimization from CY Carbide's engineering team.

.jpg)