On the grand stage of industrial production, milling inserts have become true "stars" thanks to their unique advantages and highlights. They play a crucial role on various production lines, enhancing production efficiency and ensuring product quality. Today, let's delve into the highlights of milling inserts.

Highlights of Milling Insert Materials

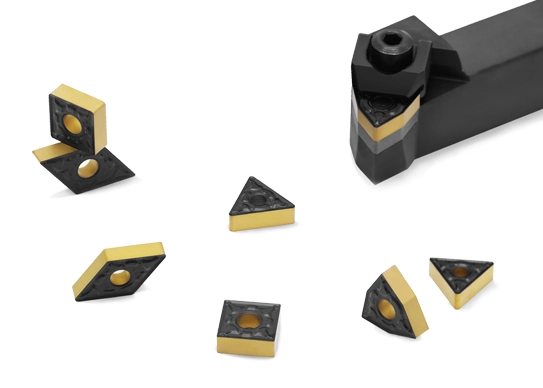

The material of milling inserts is one of its biggest highlights. Common materials for milling inserts include high-speed steel, carbide, ceramics, and diamond. Each of these materials has its own advantages. For example, high-speed steel inserts have good toughness and cutting performance, suitable for processing various materials; carbide inserts possess excellent wear resistance and heat resistance, ideal for processing hard materials; ceramic and diamond inserts have ultra-high hardness and wear resistance, suitable for high-speed and precision cutting.

Highlights of Milling Insert Design

The design of milling inserts is another highlight. The design includes the shape of the insert, the design of the cutting teeth, and the coating of the insert. These designs are aimed at improving the cutting performance and service life of the insert.

For instance, the shape design of the insert can be optimized based on processing needs to improve cutting efficiency and processing accuracy. The design of the cutting teeth can enhance the cutting performance and wear resistance of the insert. The coating of the insert can increase wear resistance and heat resistance, extending the service life of the insert.

Highlights of Milling Insert Applications

The wide application range of milling inserts is another highlight. Milling inserts can be used on various milling machines to process workpieces made of different materials. Whether it is rough machining or finish machining, planar machining, or curved surface machining, milling inserts can handle it all.

In addition, milling inserts can also be used for various special processes like high-speed cutting, hard cutting, and dry cutting. These special processes have very high requirements for the performance of the inserts, which milling inserts can meet perfectly.

Highlights of Milling Insert Maintenance

The maintenance of milling inserts is also a highlight. Proper maintenance can extend the service life of the inserts and improve their cutting performance. For example, regular cleaning of the inserts can prevent the accumulation of chips and oil that can affect cutting performance. Regular inspection of the inserts can timely detect wear or damage and replace the inserts promptly. Proper storage of the inserts can prevent moisture or collision damage.

Future Highlights of Milling Inserts

With the advancement of technology, the future of milling inserts is also full of highlights. For example, the development of new materials will provide more options for insert materials; the development of intelligent manufacturing will make the design and manufacturing of inserts more precise; the enhancement of environmental protection concepts will drive the production process of inserts to be more eco-friendly.

With their unique highlights in material, design, application, maintenance, and future potential, milling inserts have become the "stars" of industrial production. They play an essential role in various production lines, enhancing production efficiency and ensuring product quality. Therefore, we should pay more attention to the selection and use of milling inserts, allowing these "stars" to better play their role.