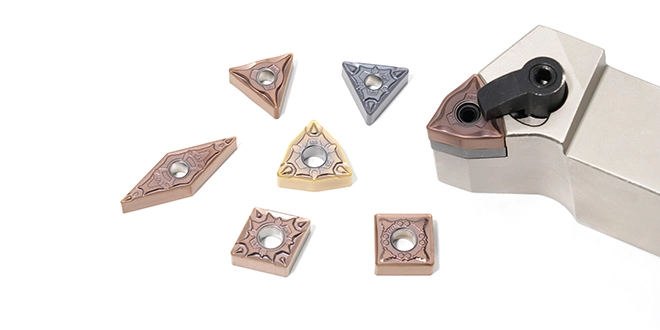

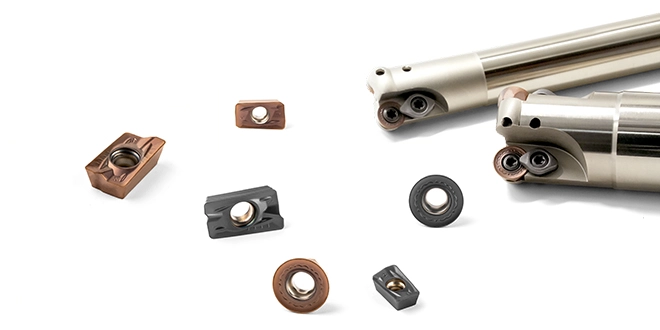

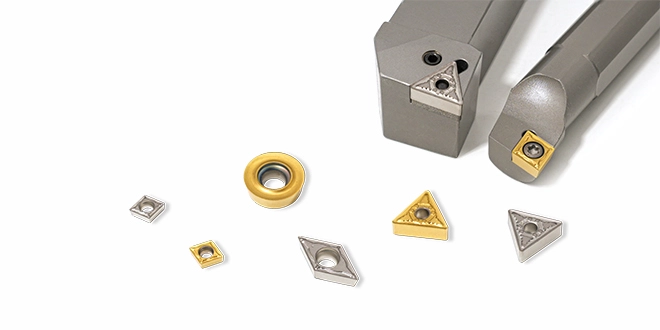

CY CARBIDE MFG.CO.LTD., established in 2003, is a professional manufacturer and exporter of cemented carbide and cermet materials. Based on 20 years of hard materials manufacturing experience, CYC set up a new brand “CYCT” for insert R&D and manufacturing. Our stable, effective and precision carbide insert products are widely used for machining P, M, K, S, N and H workpieces. Specially designed grades and types are suitable for turning, milling and drilling.

As a leading carbide insert factory in China, we offer a comprehensive range of tungsten carbide insert and CNC insert solutions. Our products are extensively applied in industries such as molds, automotive accessories, general machinery, clean energy, 3C, aerospace, shipping, railway transportation, and heavy equipment.

We pride ourselves on being top carbide insertsuppliers, providing high-quality insert carbide tool solutions. Our diverse CNC insert types ensure optimal performance and longevity, making us a preferred choice in the global market.